Solar energy is quickly becoming one of the most prevalent and consistent renewable energy sources worldwide. Whether installed on homes, commercial buildings, or large solar farms, solar panels play a vital role in capturing sunlight and converting it into usable electricity. But have you ever questioned what solar panels are actually made of?

Understanding their materials and components not only helps you gain how they work but also enables you to make informed choices when purchasing or installing a solar system. In this guide, we break down the structure, core components, and materials used to manufacture solar panels.

-

Introduction: How Solar Panels Work

Solar power has transformed the way we produce electricity, offering a cleaner, more sustainable alternative to traditional energy sources. But have you ever pondered what materials actually make up a solar panel?

Understanding the core components of a solar panel is key to recognising how it competently converts sunlight into usable electricity.

In this blog, we take a closer look at the materials used to build modern solar panels and explore how Solar Earth ensures long-lasting performance, high competence, and excellent durability in every product it manufactures.

A solar panel produces electricity through the photovoltaic (PV) effect, a process in which sunlight excites electrons inside semiconductor materials, creating an electric current.

To attain this, solar panels are engineered with multiple layers and components, each serving a precise purpose, from absorbing sunlight to protecting the cells from harsh weather.

-

What Are Solar Panels Made Of? Key Materials

Solar panels are chiefly constructed from silicon, a semiconductor material derived from quartz sand that converts sunlight into electricity (the photovoltaic effect).

This gentle silicon layer is sandwiched between a sheet of durable tempered glass on the front, which permits light to pass through while protecting against weather, and a polymer backsheet for electrical insulation.

The whole assembly is held together by an aluminium frame for structural support and uses copper or silver wiring to transport the produced electrical current.

Solar panels are chiefly made from silicon, glass, metal, and numerous protective materials. Below are the main components:

2.1 Solar Cells (Photovoltaic Cells)

Solar cells are the heart of every panel. Most are made from silicon, one of the most abundant elements on Earth.

Types of Silicon Solar Cells:

![]()

-

Monocrystalline (Mono-SI)

- Made from a single crystal structure

- Highly efficient (18–24%)

- Uniform black appearance

- More expensive

-

Polycrystalline (Poly-SI)

- Made from multiple crystal fragments

- Average efficiency (15–18%)

- Blue speckled appearance

- More affordable

-

Thin-Film Solar Cells

Made from materials like:

- Cadmium Telluride (CdTe)

- Amorphous Silicon (a-Si)

- Copper Indium Gallium Selenide (CIGS)

They are lightweight and flexible but offer lower efficiency than silicon cells.

2.2 Glass Layer (Tempered Glass)

The front surface of most solar panels is made of high-strength tempered glass, which protects the solar cells from:

- Rain

- Dust

- Snow

- Hail

- UV radiation

This glass is 3–4 mm thick and designed to be impact-resistant and self-cleaning in some models.

2.3 EVA (Ethylene Vinyl Acetate) Sheets

EVA is a transparent plastic material used to encase and protect solar cells.

It ensures:

- Cushioning

- Adhesion between layers

- Moisture resistance

- UV protection

EVA acts like a glue that holds the panel’s internal components tightly together.

2.4 Backsheet

The backsheet is the protective rear layer of the panel, usually made from polymer-based materials like PVF or PVDF.

Its functions:

- Insulate the panel

- Protect from moisture

- Increase durability

- Prevent electrical shocks

Common backsheet colors: white, black, and occasionally clear.

2.5 Aluminium Frame

A solar panel’s sturdy aluminium frame ensures:

- Structural support

- Easy mounting on rooftops

- Resistance to wind and storms

It also helps dissipate heat, improving performance during hot weather.

2.6 Junction Box

Located at the back of the panel, the junction box houses:

- Bypass diodes

- Terminals

- Wiring connections

Bypass diodes prevent power loss caused by shading on a portion of the panel.

2.7 Encapsulant & Sealants

Panels use additional materials to seal and protect internal components:

- Silicone sealants

- Polyolefins

- Laminates

These prevent water ingress and improve longevity.

2.8 Conductive Metals

Solar cells contain thin metal conductors made from:

- Silver

- Copper

- Aluminium

Silver is most common due to its excellent conductivity.

-

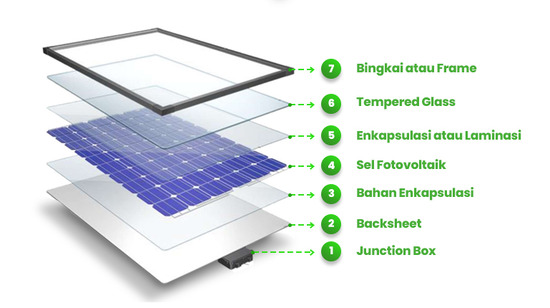

How a Solar Panel Is Structured: Layer-by-Layer

A solar panel is essentially a high-tech sandwich designed to protect the delicate energy-generating cells inside while letting sunlight through. The structure consists of five to six key layers working together:

Aluminium Frame: The sturdy outer edge that provides structural support and allows for mounting.

Tempered Glass: A durable, transparent top layer that protects the cells from hail and weather without blocking sunlight.

Encapsulant (EVA): Two layers of adhesive polymer (placed above and below the cells) that melt during manufacturing to seal the components and keep out moisture.

Solar Cells: The core layer is made of silicon that actually converts sunlight into electricity.

Backsheet: A durable polymer rear skin that electrically insulates the panel and protects it from humidity and UV radiation.

Finally, a Junction Box is attached to the back of this assembly, serving as the output interface where the electrical connectors are housed. This multi-layered design safeguards ideal performance, durability, and weather resistance.

-

Why These Materials Are Used

Each material is chosen for specific reasons:

| Material | Purpose | Benefits |

| Silicon | PV conversion | Efficient, stable, abundant |

| Tempered Glass | Surface protection | Strong, transparent, UV-resistant |

| EVA | Encapsulation | Waterproof, flexible, adhesive |

| Backsheet | Rear insulation | Weatherproof, durable |

| Aluminium | Frame structure | Lightweight, corrosion-resistant |

| Silver/Copper | Conductors | High conductivity |

| Junction Box | Electrical control | Safe wiring & bypass |

-

Environmental Impact of Solar Panel Materials

Solar panel manufacturing has a smaller environmental footprint compared to fossil fuel energy production.

Key sustainability facts:

- Silicon is abundant and recyclable

- Panels generate clean energy for 25–30 years

- Many components (glass, aluminium, some silicon) can be recycled

Modern manufacturers also follow strict environmental standards and low-emission processes.

-

FAQs About Solar Panel Materials

Q1. Are solar panels made of plastic or glass?

Solar panels chiefly use tempered glass, not regular plastic. However, EVA (a type of plastic) is used inside the panel for encapsulation.

Q2. Is silicon toxic?

No, silicon is non-toxic and safe for use in solar panels.

Q3. What material is most important in a solar panel?

Silicon is the essential material that converts sunlight into electricity.

Q4. Do all solar panels use the same materials?

Most silicon panels share the same structure, but thin-film panels use different semiconductor materials like CdTe or CIGS.

Final Thoughts

Solar panels are advanced pieces of engineering built from silicon cells, protective glass, polymer layers, metal conductors, and durable aluminium frames. Each component plays a vital role in ensuring performance, safety, and long-lasting clean energy production.

Understanding what solar panels are made of supports homeowners, businesses, and solar installers in making smarter decisions when evaluating solar technology.